As business buzzwords go, you’d be hard-pressed to find a more popular one right now than the Internet of Things: The network of machines, vehicles, buildings, you name it that collect and transmit data through the sensors and connectivity embedded in them.

In the early days of IoT, there was huge excitement about the simple possibility of connecting products and gathering data from them. Now, I hear businesses asking themselves a lot more questions.

In the early days of IoT, there was huge excitement about the simple possibility of connecting products and gathering data from them. Now, I hear businesses asking themselves a lot more questions.

For manufacturing companies, the possibilities are overwhelming. With the cost of sensors and connectivity falling and their capabilities increasing, just about anything can be monitored, at any frequency, on as many products as you like.

MAN UK, for example, gathers data on 10,000 of its trucks, generating one billion kilometers of data every year on factors such as vehicles’ condition, how they’re being driven, routes taken and more.

But no matter what you decide to measure, all you get back is raw data. Without a plan to analyze the data to generate insights, and then use these to provide services that give tangible value to you and your customers, it isn’t worth doing.

New Business Models

The really exciting thing about IoT is that it enables companies to develop entirely new business models around providing services to customers. This means you can create brand new revenue streams, not just improve on the existing ones.

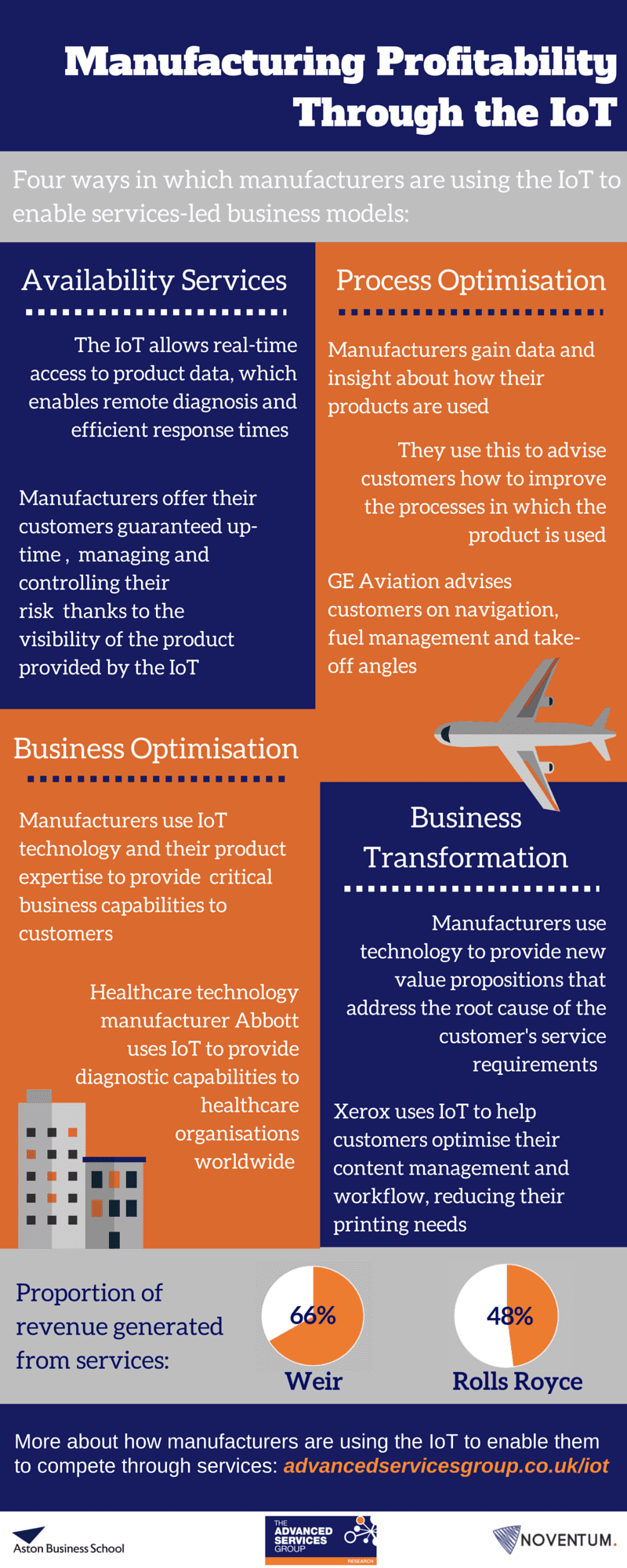

There are four possible types of business model, all designed around services that help the customer to be more successful.

There are four possible types of business model, all designed around services that help the customer to be more successful.

In each case, the manufacturer combines its unique expertise of the product and its use, with its understanding of the customer’s needs, to offer a service made possible by the insights gained through the IoT.

The connectivity also means services can be provided remotely, so they can reach increasing numbers of customers, or new customers that are located a long way away.

Providing services that are enabled by the IoT also gives manufacturers direct, continuous insights into the customer’s needs. This means they can create offerings that differentiate them from other providers, and spot opportunities to add new services for the customer.

The Impact

Manufacturers are recognizing that competing through services strategies that incorporate IoT and help customers to achieve and improve on their own core business is a sustainable way to grow. Rolls-Royce, for example, achieves 48 percent of its revenue from services, while the mining equipment company Weir generates even more — nearly 66 percent. Our research has shown that manufacturers following this kind of strategy can expect 5 to 10 percent sustained growth per year.

The challenge manufacturers now have to face up to is not how to get the data from their products, but to design the business models that will help them make money from the data.

More about this research, which was conducted in partnership with Noventum, and accompanying resources and training workshops can be found at www.advancedservicesgroup.co.uk/iot

“Big Data” is always RAW DATA, that is the requirement, so that some miracle software sold by some vendor will be able to look at said big data and quickly develop insights that will instantly assure a huge increase in profits and shareholder value. At least that is the message that has been trumpeted at us hourly for the past two years. Now this post is telling us that the internet of everything you can possibly imagine is going to be sending us all of these gazillion gigabytes of raw data at an astounding rate. Therefore all of us must first purchase their special software that works miracles and produces instant knowledge based on that data. AMAZING!!!