A lot of workers worry that their job may some day be performed by a robot. Sometimes, though, it’s nice to be able to send a machine into a dangerous spot in place of a real-life person — like deep ocean engineering — and the upside of having these complex machines is that a real person has to fix them when they malfunction.

Darrell Martin is an example of the man behind the machine. He’s been a senior field service technician for Deep Ocean Engineering in San Jose, Calif. for nearly 23 years, although he’s known colloquially there as just “the field guy.”

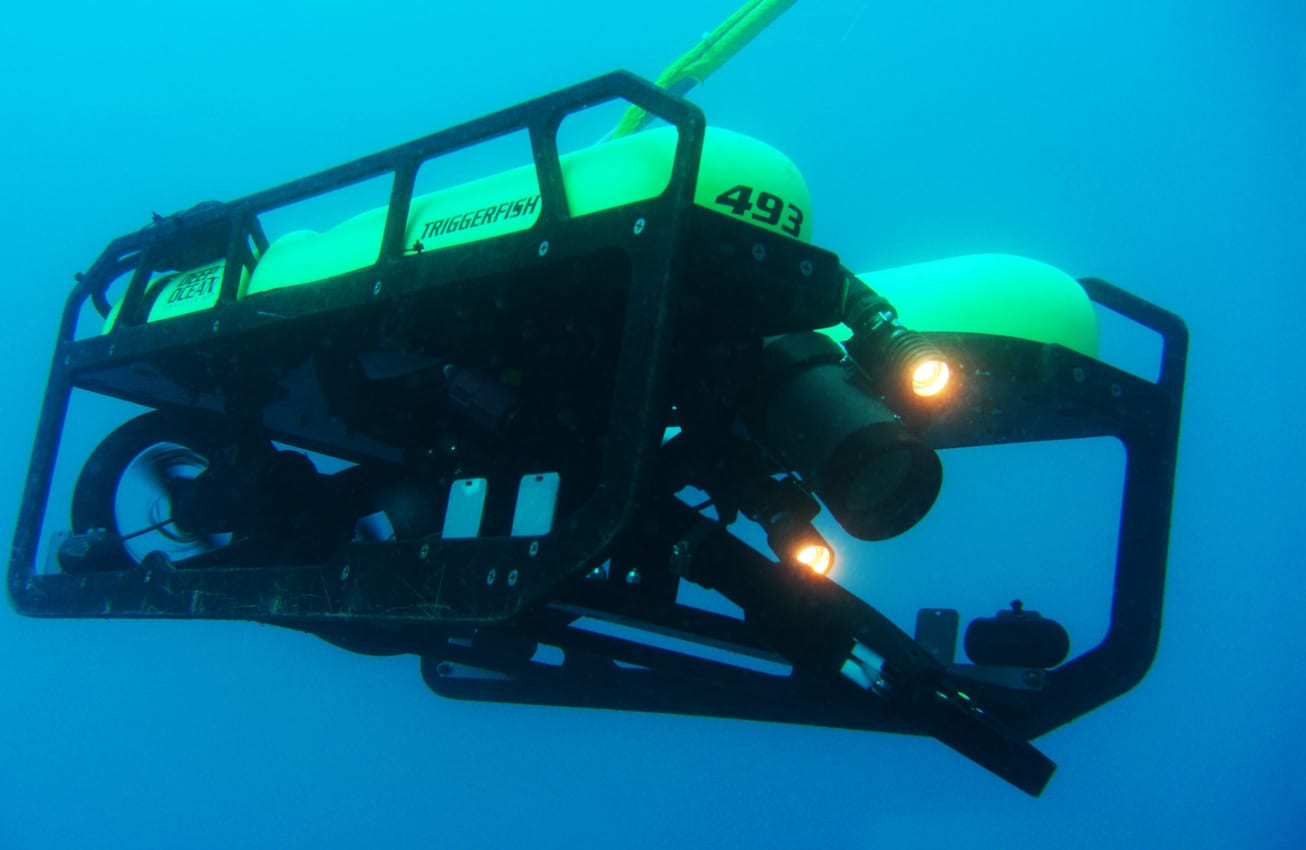

Deep Ocean Engineering is a company that builds, designs, and manufactures remotely operated vehicles (ROVs) sent in to do the dangerous work that human divers cannot perform. These ROVs are typically outfitted with a camera that lets technicians above water check out a repair job on a ship’s hull, or an underwater pipeline, or or the face of a dam. The ROVs are generally classified as either for observation, or as “light work” machines.

Deep Ocean Engineering is a company that builds, designs, and manufactures remotely operated vehicles (ROVs) sent in to do the dangerous work that human divers cannot perform. These ROVs are typically outfitted with a camera that lets technicians above water check out a repair job on a ship’s hull, or an underwater pipeline, or or the face of a dam. The ROVs are generally classified as either for observation, or as “light work” machines.

Deep Ocean Engineering’s ROVs are deployed for a range of clients, including some in the nuclear power-generation industry. In this particular area, ROVs the size of a toaster are equipped with cameras are sent deep below the surface to support offline nuclear reactors and their fuel. The reactors are kept underwater because water is supposedly excellent at shielding radiation.

SEE ALSO: Afraid of Heights? Well, Don’t Become a Wind Turbine Technician

The company also works with the U.S. Department of Homeland Security. Deep Ocean Engineering provides ROVs for search and recovery missions when county sheriffs and police units need assistance. Martin recalled one such incident where the ROVs brought in more than police bargained for: The sheriff’s department was looking for two men who’d fallen off a fishing boat and disappeared. But instead of just finding the two men, the ROV spotted seven — it cleared up the sheriff’s disappearance files going back almost 15 years, he said.

Commercial diving companies also use the ROVs for inspections of pipelines, ship propellers, and hydro-electric power facilities — basically any area that’s too dangerous for humans. Martin even mentioned working with treasure hunters over the years.

Commercial diving companies also use the ROVs for inspections of pipelines, ship propellers, and hydro-electric power facilities — basically any area that’s too dangerous for humans. Martin even mentioned working with treasure hunters over the years.

Martin’s role in all of this is as “Mr. Fix-It” — the guy with the right tools when the ROVs do the wrong things. He’s sent in to address mechanical problems when these machines, which frequently bump into rocks and things below the surface, get dinged up. Plus, all the extra parts and cables connecting the ROV to the topside — they call those the umbilicals — have to be accounted for, too.

“The umbilical closest to the ROV gets pulled over, around, and through every rock, tree branch, and abandoned automobile the ROV goes through,” Martin said. “Our most aggressive operators will need to cut and re-terminate their umbilical using soldering and waterproofing skills once per year.”

Martin carries a kit that weighs just under 50 pounds, and holds every tool he needs for the job. It includes a soldering kit, heat shrink and wire strippers for umbilical repairs, topside repairs, and fixing or upgrading cabling; adjustable, open-end, and socket wrenches for any sort of tightening; a multi-meter to check or confirm power levels; bags of wire, resistors, and electrical connectors and pins and housings for upgrades; and your most basic hand tools like screwdrivers, hammers, hacksaws, and pliers for everything else.

Martin also needs to know the details of every different kind of ROV his company manufactures, from the Firefly, which is typically used for pressurized water reactors and boiling water reactors, to the Triggerfish, used for harbor and vessel security operations.

The robots can make for some strange stories on the job. Martin said he’s seen ROVs used for all kinds of things, from trying to recover a submerged 747 jet engine on the ocean floor, to hunting for clues to help solve a mystery about why a fishing boat sank.

While part of the job description involves traveling to locations to monitor and repair ROVs sent far below the surface, Martin has some typical daily duties that he has to tend to as well, such as writing quotes, attending trade shows, accept purchase orders, and explaining technical issues to customers (which can be one of the hardest parts of the job, according to Martin).

Martin said dealing with the “fix-it-now” type of customers can be more difficult than repairing the aquatic robots. But despite the occasionally demanding customer, Martin says he genuinely loves what he does.

“I like my job very much,” Martin said. “The best part is it is different every day and I enjoy supporting customers. The worst part, as time goes by, is the travel by air. That is an industry that needs to be taken over a knee.”

So one smart person can take away the jobs of many?

That’s not very comforting to know in this economy.