There continues to be an increasing amount of great research and content published about equipment-as-a-service and outcome-based business and engagement models. It is quite likely that these will be a critical part of how organizations deliver products and services in the near future. It is also likely that customers will resort to consuming products and services in this manner given the financial and other benefits extolled. In my opinion, it is more likely that these types of engagement models become one part of a product and service delivery portfolio.

There are many transformational elements that need to take place before manufacturers can deliver equipment-as-a-service. This includes connectivity into assets, the recognition of the installed base, the validation of output delivered, and the commercial infrastructure to support these models. But prior to evaluating all these gaps, there are two fundamental questions about as-a-service models that still need to be answered. I don’t have the answers to these but would like to create a dialog among the service community to find out.

- Are products being designed with outcomes in mind?

- Are customers actually demanding outcomes?

Let’s discuss the first question in this article and dedicate the next one to question two.

Are We Designing for Outcomes?

Late last year, I spoke with Mark Wilding on the topic of outcome-based services and why we hadn’t seen more progress in this area. At the time, Mark was Director of Global Service & Support at Hexagon Manufacturing Intelligence, but now is Vice President of Global Transformation at ServiceMax. To level-set, Mark is extremely knowledgeable and passionate about all digital transformation-related topics, particularly in service’s role in driving transformations forward.

On the topic of outcomes, Mark suggested that manufacturers are likely in a position to craft commercial offerings that promise outcomes, but that they don’t have the central product development infrastructure set up in support. Essentially, products aren’t designed with outcomes in mind. Mind you, we’re speaking about critical assets and equipment and not products that can be easily disposed or swapped for a new one. The more I heard from Mark, the more I agreed with his sentiment. It eventually comes back to this idea that we can’t achieve success in digital transformation if we continue to digitize in silos. It’s the same with equipment-as-a-service models. These can’t be successful if they are only being supported by the service organization or the sales organization. The initiative needs to be organization-wide.

So, let’s think about what a product designed with outcomes in mind should look like. In my mind, it breaks into 5 sub-areas, all of which are connected. Let’s spend a little bit of time on each.

Design for Connectivity

Connectivity is critical to the delivery of outcomes in many ways. At first, it enables the ability to track and verify that outcomes are being delivered. And it is essential to increase the uptime and reliability of the asset as delivered with predictive maintenance, remote support, issue triage, or field-based resolution. All these disciplines are much more effective with the support of connectivity, and for this it is essential that outcome-generating assets can deliver the right type of information to critical service stakeholders.

Design for Serviceability

This is a very complex topic and one that has been on the table for decades. The idea here is that products should be designed in a way where the interval of planned service events is increased or made entirely-performance based (as enabled by connectivity) and that the time of actual install or service event completion is made shorter. For instance, if a piece of equipment breaks down, it should be easy for the technician to triage the issue and determine an appropriate resolution. Can the equipment itself surface information that assists with the triage or diagnosis process? Once repair is needed, are the components that need repair or replacement easily accessible so that the disassembly and reassembly process can be made less complex.

[Related Reading: Looking to Design-for-Service? Start Here]

Given workforce and other supply chain constraints, there are additional flavors to the topic based on who is completing the service action (install, repair, upgrade, and more) and where the action is being done. For instance, can the product be designed with self-service in mind, where the customer can easily determine the issue and use replaceable units to get up and running? Or can the product be designed in a modular fashion where lower-skilled technicians, as part of the customer’s organization or a third-party workforce, can swap in field replaceable units and send faulty modules back to a depot for more substantial repair? This ensures that the asset is up and running and delivering the outcomes that the customer needs. More so, it allows the manufacturer to centralize its higher-skilled resources in a depot setting to work on more complex repairs. These repair models have various implications on parts and workforce planning disciplines, but they can have a measurable impact on increasing uptime and output delivery.

Design for Customer Adoption

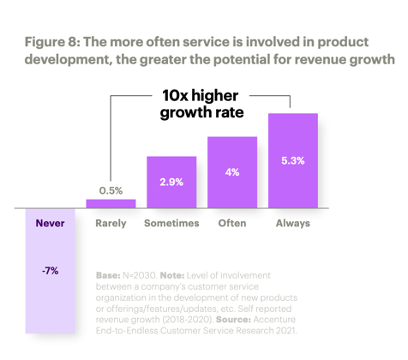

Source: End-to-Endless Customer Service. Accenture 2022

A recent white paper from Accenture highlights the significant value inherent in a collaborative approach between product development and service feedback.

Some of this value is attached to the incremental feedback that service can deliver back to product to increase reliability and improve performance. In the absence of connectivity, service becomes the de-facto bridge for capturing and delivering asset data to relevant stakeholders.

But what often gets overlooked, is the insight that service has into the broader context of how a customer is using the features of the product to drive outcomes. Which features in the product are the most critical to customer outcomes and therefore need to be reinforced or made easier to access vs. those that are nice to have but not essential to customer outcomes?

It’s the features in the former category that need to be a central part of the product development strategy. More so, identification of these value-added features opens up opportunities for the organization to layer in customer success initiatives and adoption services that ensure the amplification of these features to meet customers’ needs.

Design for Performance

This section could be called designed for updates but is tied to the avenues available for the manufacturer to upgrade the performance without a full-scale replacement. This might come from firmware installed on the asset or additional software offerings that bring new capabilities to life. We experience these all the time in our consumer lives, especially when it comes to consumer electronics, but are also beginning to see it when it comes to heavier assets such as automobiles. Improved performance may also come via replaceable components that can be swapped out for upgraded parts.

Design for Circularity

Replaceable components find their way into several parts of this blog, but they can play a major role in supporting an organization’s outcome-centric and circular ambitions. If parts can be replaced, repaired, refurbished, recertified, and eventually re-inserted into installed products, then they can extend the life of the asset and continue to support the delivery of outcomes. This can significantly impact the financial and environmental cost of the outcome delivered making the model even more feasible for both manufacturer and the customer.

This change to design for outcomes is a critical piece in the success of as-a-service initiatives. It will:

- Reduce the commoditization effect as outcomes are harder to commoditize

- Create a more enticing proposition for customers

- Move decision making from price to value more closely aligned with customer needs

The change won’t be easy as most design in an industrial system is mostly focused on moving product and enhancing features and capability. This generally creates a higher dependency on resources and experience for installation and support. While capability enhancement continues to be essential to the delivery of outcomes, designers also need to think about de-skilling the actions necessary for guaranteeing the outcomes of the product. To accomplish this transition, designers need to strategically connect with their service leaders and need to be brought in to the overall as-a-service value proposition.

[More on the circular economy: Service Is at the Heart of the Circular Economy]

Share this: