Our world has increasingly gone hybrid – and the service experience is no exception. The Internet of Things (IoT) and other remote technologies are gaining adoption and starting to have a greater impact on how service is effectively delivered. Service organizations can now embrace a mix of in-person and remote options to operate with greater efficiency, reduce carbon footprints, and deliver an exceptional customer experience.

In a recent ServiceMax webinar with guest speaker Paul Miller, VP and Principal Analyst at Forrester Research, the state of industrial IoT was explored including its impact on field service. Organizations are now adapting with an agile strategy that incorporates remote support in today’s increasingly hybrid world. Let’s take a look at a few of the key takeaways.

Watch the complete webinar here: VIEW RECORDING

4 trends that are shaping the future of manufacturing

Miller shared some key insights about the future of manufacturing:

- Integrating digital technologies with physical products: This includes remote monitoring (ex: IoT sensors) that collects data on how a machine is performing, which drives predictive maintenance and predictive scheduling to improve asset utilization, and apps like ServiceMax Engage that facilitate remote support.

- Embracing local, near, and far manufacturing capacity: This is a rebalancing of where work is being carried out and how we source goods, partly driven by geopolitics and partly driven by the supply chain disruptions experienced post-COVID.

- Electrification, decarbonization, and sustainable manufacturing: This is becoming more and more important to manufacturers around the world that are trying to understand how to move from fossil fuels, improve energy efficiency, and embrace various forms of electric capability.

- Balancing the automation triangle: This trend is particularly important for the service experience, as it’s about figuring out how software and hardware can be automated to augment the human workforce to improve productivity in an environment where it can be difficult to hire and train new workers.

“Industry 4.0 emphasized hardware and software automation but sometimes forgot the people,” Miller argued. “Machine learning, AI, and robots can be transformational but they don’t replace most of the people. We need to balance the strengths and weaknesses of software, hardware, and the human workforce so they work together in harmony.”

Miller pointed out that the smart use of digital technologies augments the human workforce in various ways. For example, technology can be used to effectively capture knowledge from experienced workers, which can then be easily transferred to colleagues. This can then result in improved visibility into assets and operations, reduced costs around transportation, and an enhanced customer experience with faster first-time-fix rates.

6 reasons why you need to add remote options to your strategy

Miller identified six main reasons why it’s important to implement remote capabilities to field service execution and invest in improving remote tools, processes, and workflows now and in the future:

- COVID-19: The pandemic forced a change in behavior. Customers saw first hand that remote support was a viable option.

- Connected machines: OEM manufacturers are increasingly shipping connected assets, and end users are now better understanding the value – for themselves, the OEM, and the field service organization.

- Workforce constraints: An aging workforce, a competitive labor market, and a need for new skills have made it necessary to use various forms of automation (and AI) to augment existing staff to make them more efficient so they spend less time on routine tasks.

- Smarter software: AI, machine learning, and robotic process automation generate valuable data that can be analyzed and used for predictive maintenance.

- Sustainability: Reduce truck rolls to save fuel, reduce unnecessary part replacement to minimize waste, and keep assets running properly to save energy and extend asset life.

- Servitization: More organizations are aspiring to servitization or product as a service, which requires connected machines and effective field service to make it viable.

As a result, remote engineers can triage connected machines to quickly understand the state of an asset prior to a site visit – and in some instances, avoid a truck roll. Remote experts can also augment and guide local customer talent and field service teams. This means interventions become less scheduled and more responsive. Technicians traveling to a site will already know what they’re going to fix, how to fix it, and carry the parts to fix it.

What ServiceMax is hearing from its customers

In the second part of the webinar, Gabriele Bodda, Vice President of Product Management, ServiceMax at PTC, then shared some customer feedback, including how customers are connecting to physical assets to perform remote service, and how this connectivity is accelerating digital transformation programs.

OEM, manufacturers, and service providers that are ServiceMax customers are specifically concerned about the following themes:

- Siloed field service processes reduce efficiency: Data often flows into a database but insights don’t get passed to the entire field service organization (or other functional groups).

- Higher customer expectations for service quality: Software has empowered customers, who expect technicians to come better prepared and able to carry out the task.

- Increasing the number of connected devices: Currently, only about 5% of ServiceMax users have IoT-enabled equipment, as it can take a while to replace legacy machines.

- Greater interest in exploring new business models: Manufacturers are increasingly seeking new ways to add service revenues to the bottom line as a predictable revenue stream that can provide competitive differentiation, such as by delivering outcome-based service models.

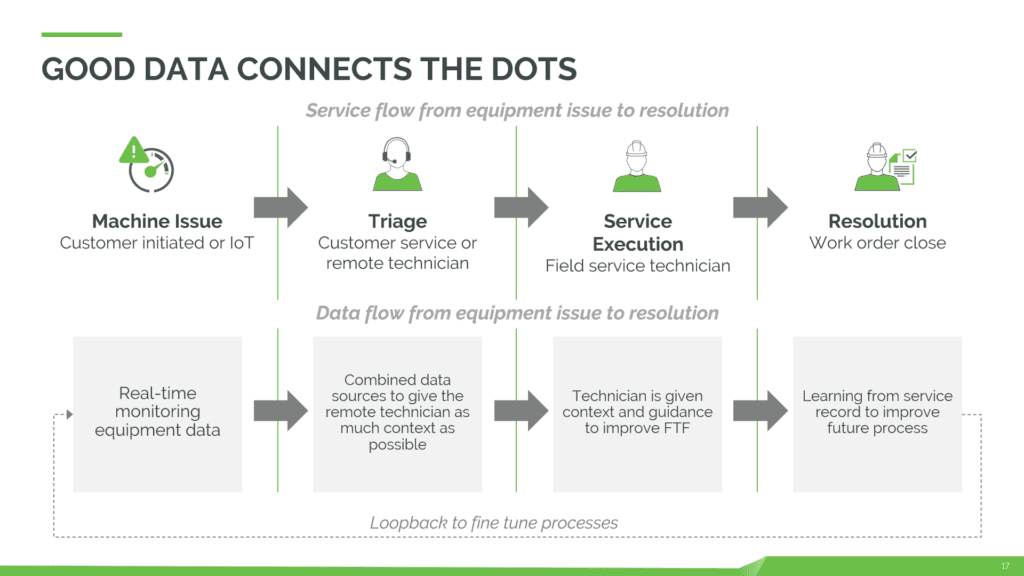

Good data connects the dots

Bodda then explained what kind of principles need to be applied to come up with a remote-first strategy.

First, data that identifies an issue with a machine, initiated by the customer or by IoT sensors, needs to flow freely through the organization. This information needs to be available to the customer on site or to a remote technician – and then to a field service technician should further assistance be needed. The goal is to better assess issues faster, identify the root cause, and remedy the situation quickly.

As data flows through the organization in real time, its quality and timeliness needs to be better. This way it becomes more useful and can give technicians sufficient context to identify symptoms and make hypotheses about potential solutions. Software that provides the remote service engineer with access to service history and asset details is critical. Technicians can also connect remotely with colleagues and customers to guide them through a few steps to gather as much data and context as possible.

That data is then documented, so when it’s shared with the field service organization, the technicians instantly have all the information needed to deliver service effectively. They can also analyze the data to learn from the service record and improve future processes.

“The next time a machine issue comes up, the error codes can be automatically mapped to potential symptoms,” Bodda pointed out. “They’re recognized as typically related to a certain root cause, which is then mapped to the most likely solution. By the time somebody looks at the problem, it’s already 80% resolved. That’s the ideal situation.”

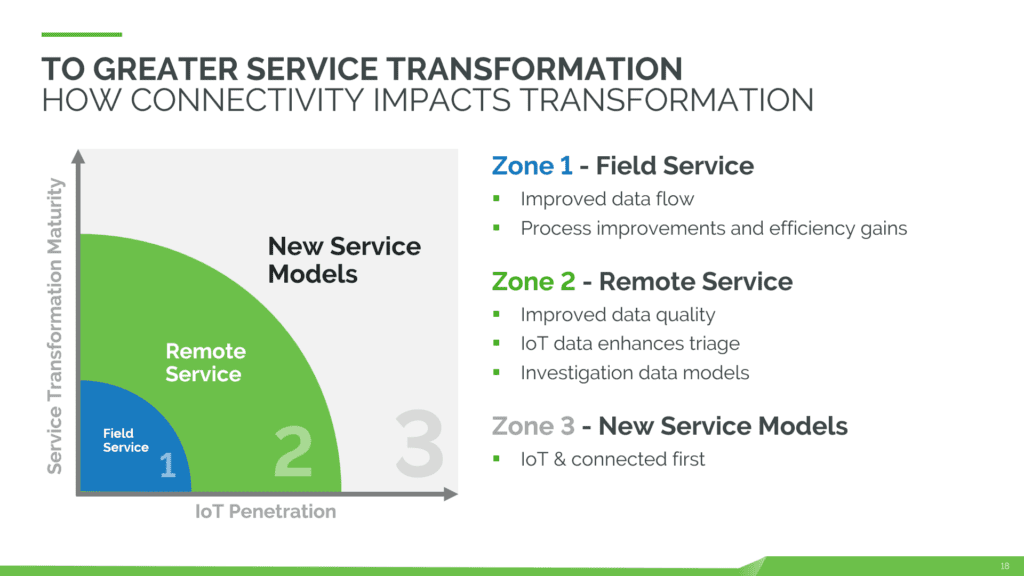

How connectivity impacts digital service transformation

IoT is not mandatory for a remote-first strategy. The alert about a machine issue could come from an email, text, or a phone call. However, once you start using connected machines, there are immediate gains for your field service delivery.

Customers benefit right away from an improved data flow, an enhanced process, and efficiency boosts. Once the IoT penetration hits a certain percentage of a customer’s equipment and devices, the adoption of remote service contributes to exponential results. Better data quality means remote technicians don’t just gather data but analyze data models, which empowers them to do something about the problem.

“Connectivity really becomes inevitable once you move into new service models,” Bodda explained. “If you want to sell outcomes, you need to be able to monitor outcomes. And that means you should be able to monitor the machine itself. The most likely way you’re going to do that is by having data flow through sensors into your remote control center where your engineers can act. That’s how you scale and deliver service across your installed base.”

To conclude the webinar, Bodda shared a customer story about Elekta, a global company that produces medical devices and software used to improve the lives of people with cancer and brain disorders. Elekta chose ServiceMax for their field service management platform and launched a pilot of a Connected Field Service solution with remote access. This solution connects previously offline machines directly to technicians in the field.

As a result, Elekta was able to solve 30 to 40% of all issues remotely. Of the cases that couldn’t be solved remotely, 67% could at least be assisted remotely. Every year, the company now also delivers over 600 preventative actions, which has led to more than 14,000 uninterrupted treatments for patients. It also saved more than 1,200 clinical hours, which has had an immediate impact on patients and their lives.

Interested in learning more about why you now need a remote strategy? Watch the complete Forrester webinar here: Why You Need a Remote Service Strategy.

Share this: