I had the pleasure of meeting Dr. Michael Grieves back in 2002, just after he published a white paper that presented a compelling case for manufacturers to leverage a Digital Twin. At that time, sufficient technology didn’t exist to fully bring his vision to market. Today it has. The concept of a digital twin has morphed and expanded a lot over the past two decades. The Digital Thread has emerged to become a key component to ensure Digital Twins stay accurate. At the PTC 2023 LiveWorx event, I had an opportunity to host a panel discussion on the role of a digital thread. I’ll expand upon our discussion here for those who might have missed the live presentation.

The panel I had the pleasure of working with included Matthew Littlefield, President, and Research Lead at LNS Research, and Mark Wilding, VP of Global Customer Transformation at PTC. We began with defining asset centricity, given its importance in extending the digital thread to the field where industrial assets are used and maintained.

“Asset Centricity is a best practice when servicing an industrial asset. Simply stated, it is a strategy to assess performance from an asset’s perspective at the asset to gain access and visibility into how it runs.”

This is such an important topic today that the term Product Lifecycle Management (PLM) is now more commonly being refined to feature Service Lifecycle Management (SLM) more prominently. This is especially the case when discussing a Digital Thread strategy.

A digital thread is enriched when data is collected on how an industrial asset runs, uses energy, and integrates within its operating ecosystem. As field service or repairs are conducted, this information needs to be included to help optimize the useful life of the asset, support future updates, and help minimize the impact of future potential recalls. When actionable data is available promptly, it’s possible to be more proactive with maintenance and service strategies to ideally eliminate unplanned downtime.

What Data Can Be Collected?

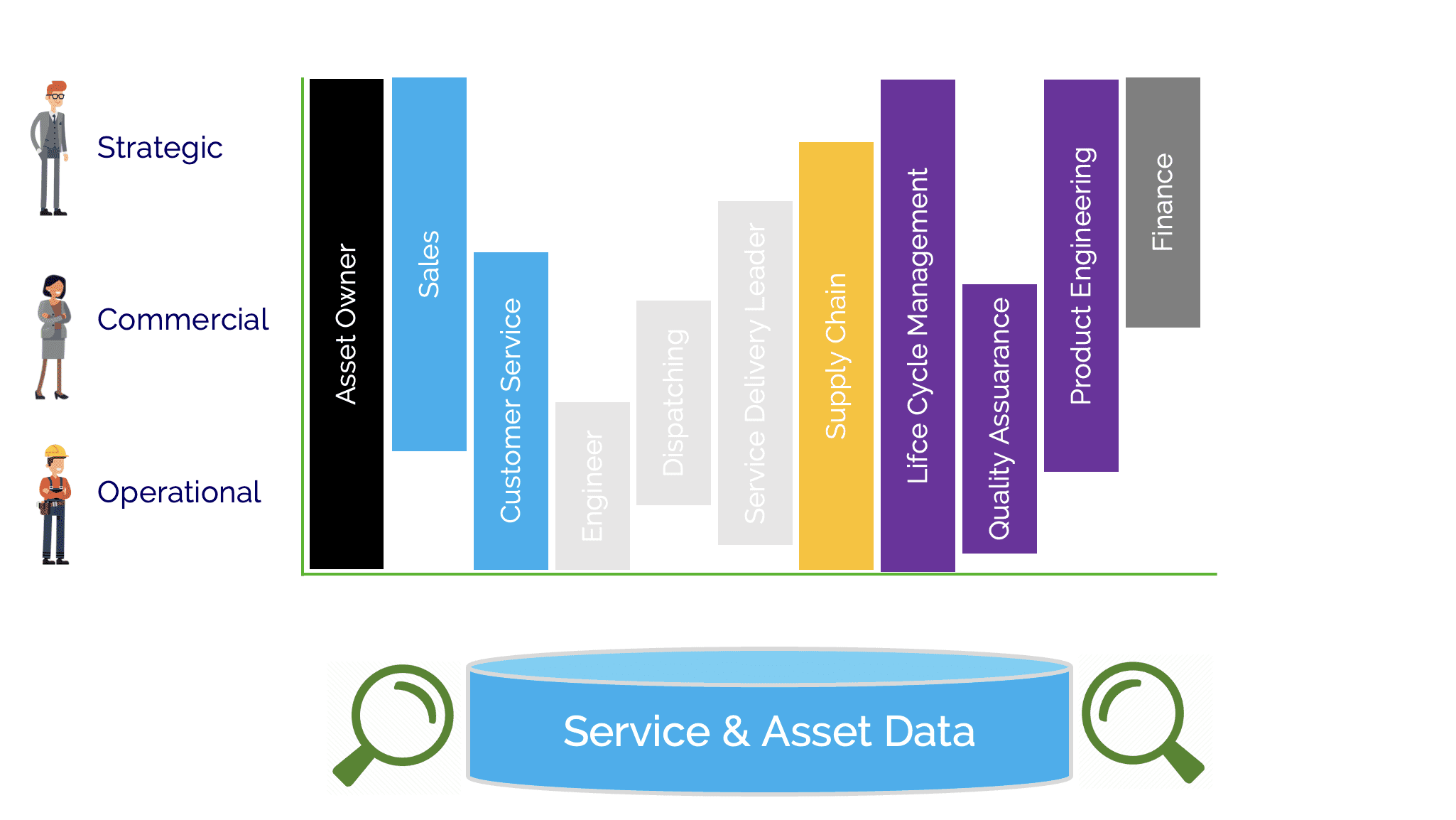

Mark shared with the audience examples of the types of data that should be included and collected from service operations. This information can then become part of the digital thread, which can be shared with operators, other divisions, and ideally, back to the original product designers for future enhancements. This data is far-reaching. It can be grouped into Strategic, Tactical, and Operational data – each used by various personas at manufacturing, service, and end-user operations. Here is a diagram that illustrates the vast amount of data that can now be collected:

How Has the Role of a Digital Thread Evolved?

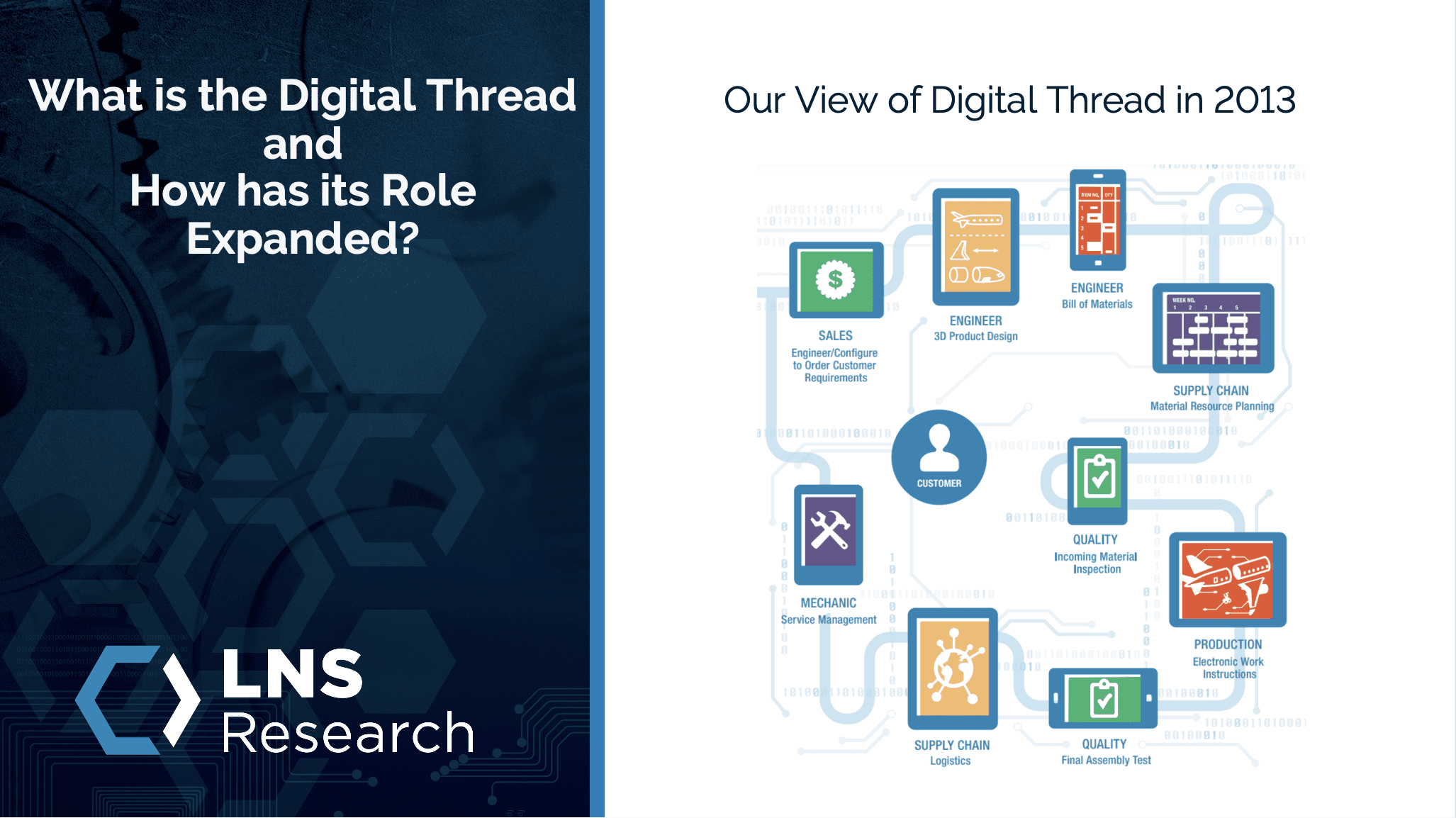

Matthew Littlefield then shared a few diagrams that LNS Research has presented over the years on how to build and maintain a digital thread. The first image he shared dates back to 2013. It reflects a closed loop spanning design, supply chain, production, quality, sales, and service management, as shared below:

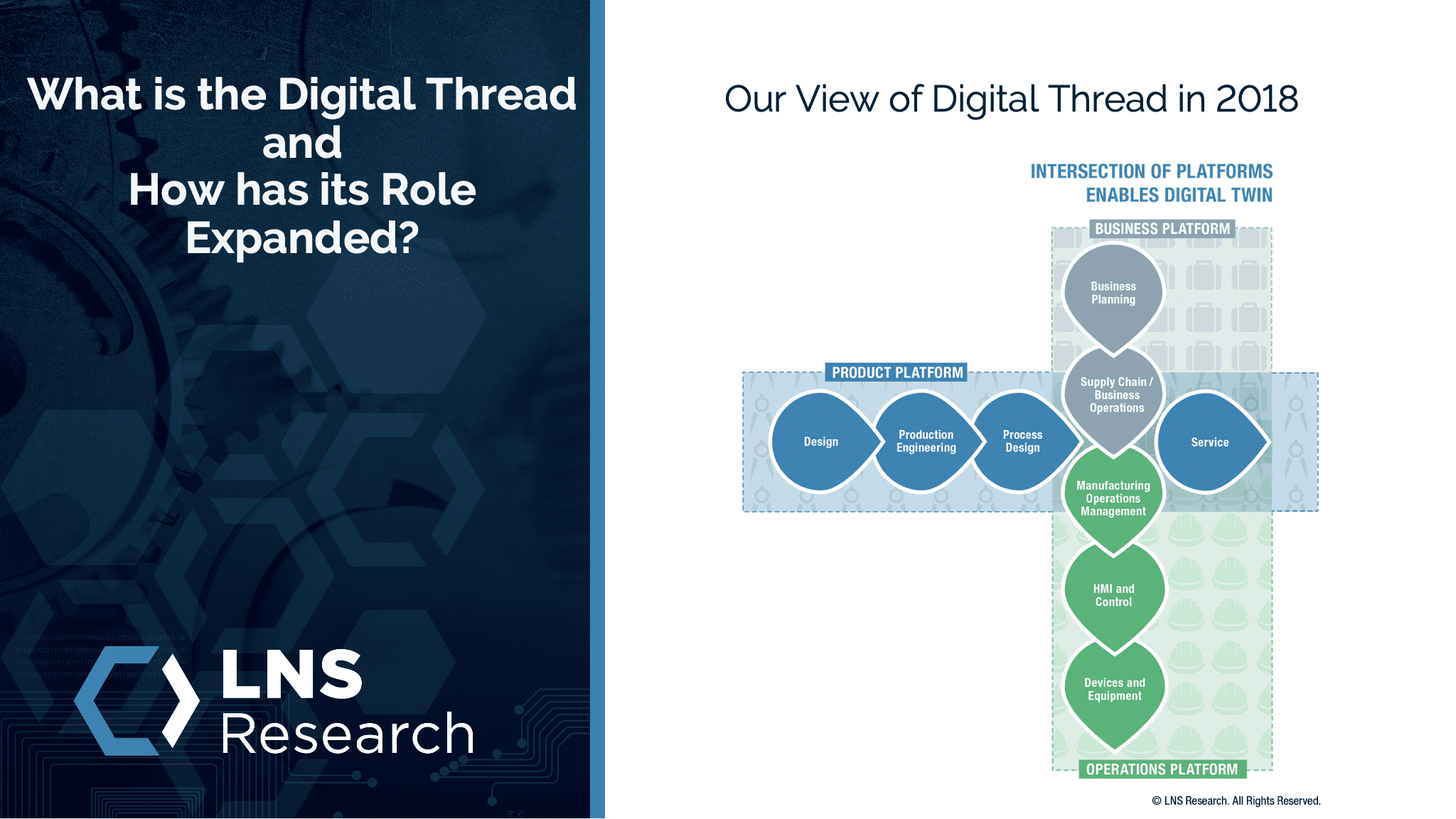

The next image, dating back to 2018, reflects more of an intersection between product design through service and the manufacturing process. Two distinct platforms were seen as the best practice where each discipline could operate at scale by pooling resources and applications across each respective platform that could be operated with limited interaction. Here is a copy of that image:

Then, along came COVID and everything changed. We all learned about the challenges of disruption, supply chain issues, and the need to operate at scale and with agility and resilience as the new best practice. Architectural application models were reviewed and reassessed on how best to define and maintain a digital thread.

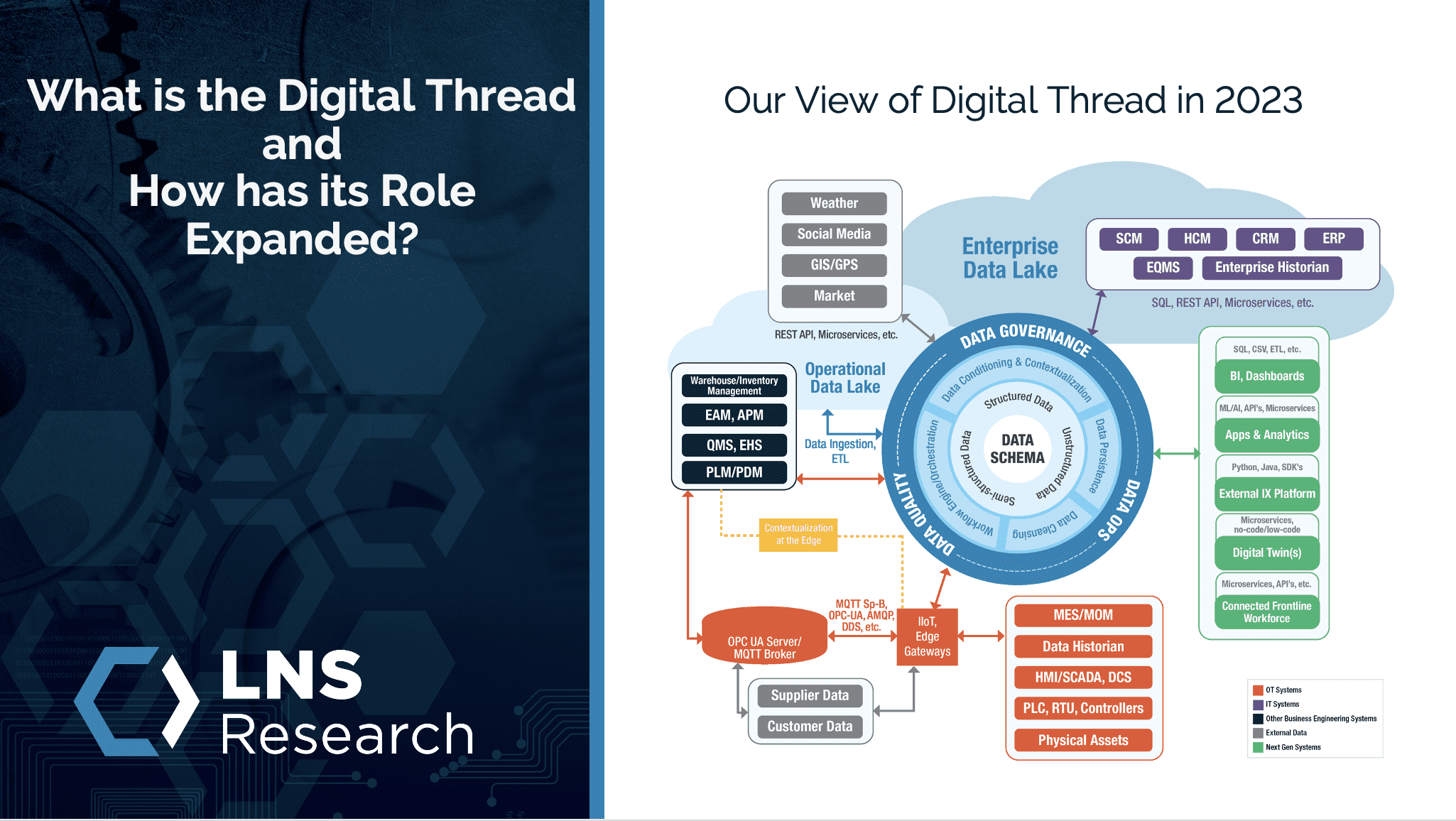

Another key development emerged in the COVID years – an increasing reliance on automation, Artificial Intelligence, and machine learning. Each of these technologies is heavily dependent upon collecting data, at volume, and as near to “real-time” as possible. The more data, the better! The thirst for data has spread across the entire enterprise. This shift has occurred at such a level that digital strategies have evolved to now focus on how best to enable data-driven decision support.

This brings us to LNS Research’s current view on the role of a digital thread, as shared below:

Data has become critical to every organization. It is increasingly shared and used to perform every operation. This strategy adds agility to every department. Now production can change faster, market intelligence can be acted upon with greater efficiency, and new product designs can be launched faster and with greater success.

The Closed Loop Vision of PLM and SLM

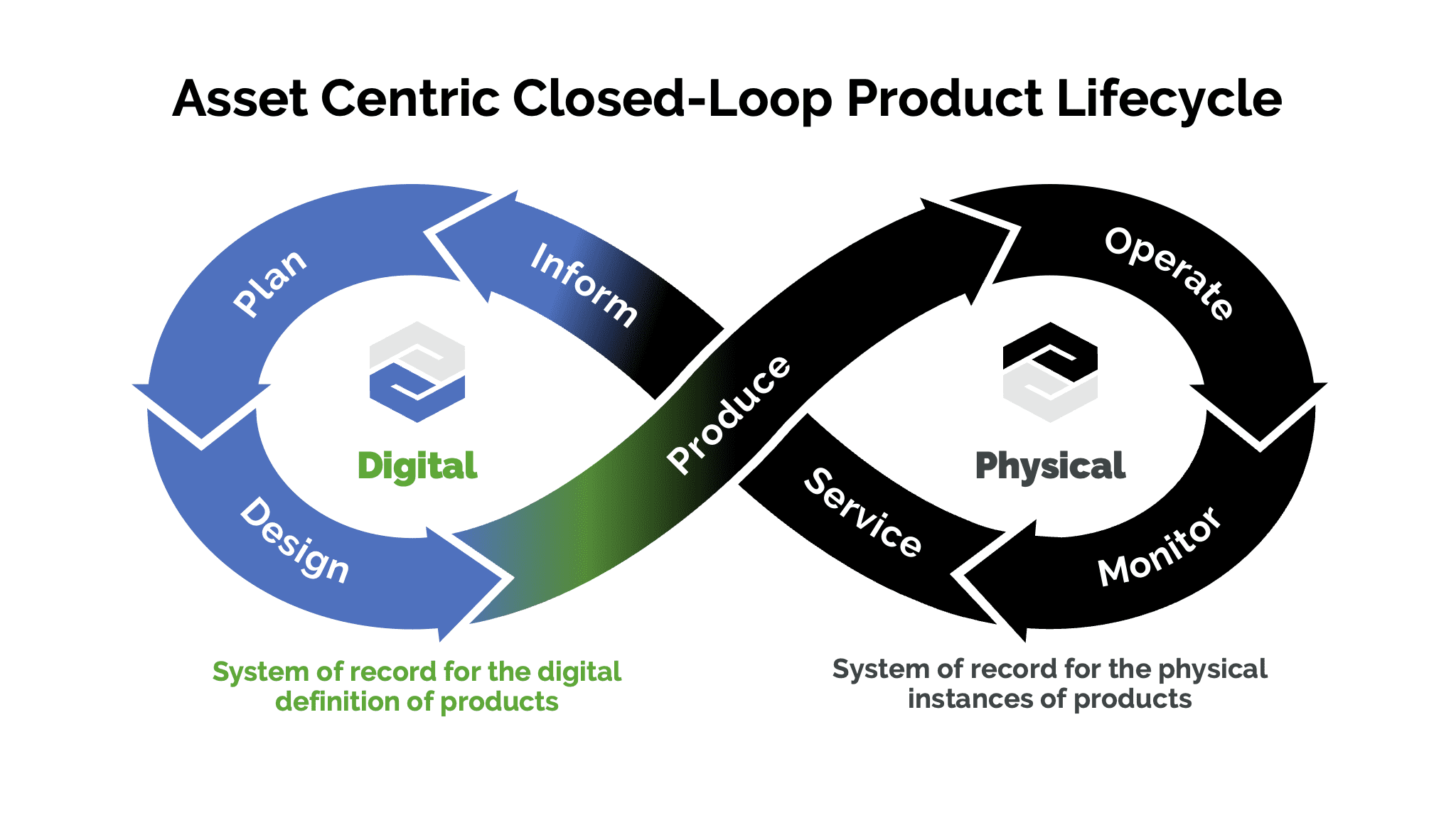

PTC is doing its part to help usher in this new realm of data sharing and digital thread expansion. Its acquisition of ServiceMax made a big impact on completing its vision of establishing a closed loop of data sharing across an asset’s entire lifecycle. Instead of viewing a digital thread as a linear progression from “cradle to grave,” a better way to visualize this concept is as an infinite loop that never ends. This concept plays out well when operational agility is a critical factor.

The world is not likely to go back to predictable, static marketplaces. Disruption occurs faster and with greater frequency. The role of a Digital Thread will likely continue to evolve. In this type of environment, the need to build resilience into systems and operations has never been higher. Here is an image of an asset-centric closed-loop product lifecycle that mirrors the next generation of digital thread. It is a great representation of how manufacturers must think to best drive innovation, customer satisfaction, and competitive differentiation.

Future Impact on Industrial Transformation

Not only has the architecture and vision of a digital thread evolved over the past few years, but so too has its impact on the broader manufacturing industry. No longer is it just operations or service departments that require access to this broader scope of digital thread data. New business initiatives have emerged that have elevated the importance of asset data. Take sustainability programs, as one example. Manufacturers are now more mindful of their carbon footprint, what suppliers were utilized, and what other related processes were part of each product’s production and assembly process.

Employee well-being, satisfaction, and career paths have become particularly important, given the limited amount of skilled and trained resources available. Employee retention programs are driven in part by the data collected to both assess performance and allocate resources. The list of new corporate initiatives continues to expand every year!

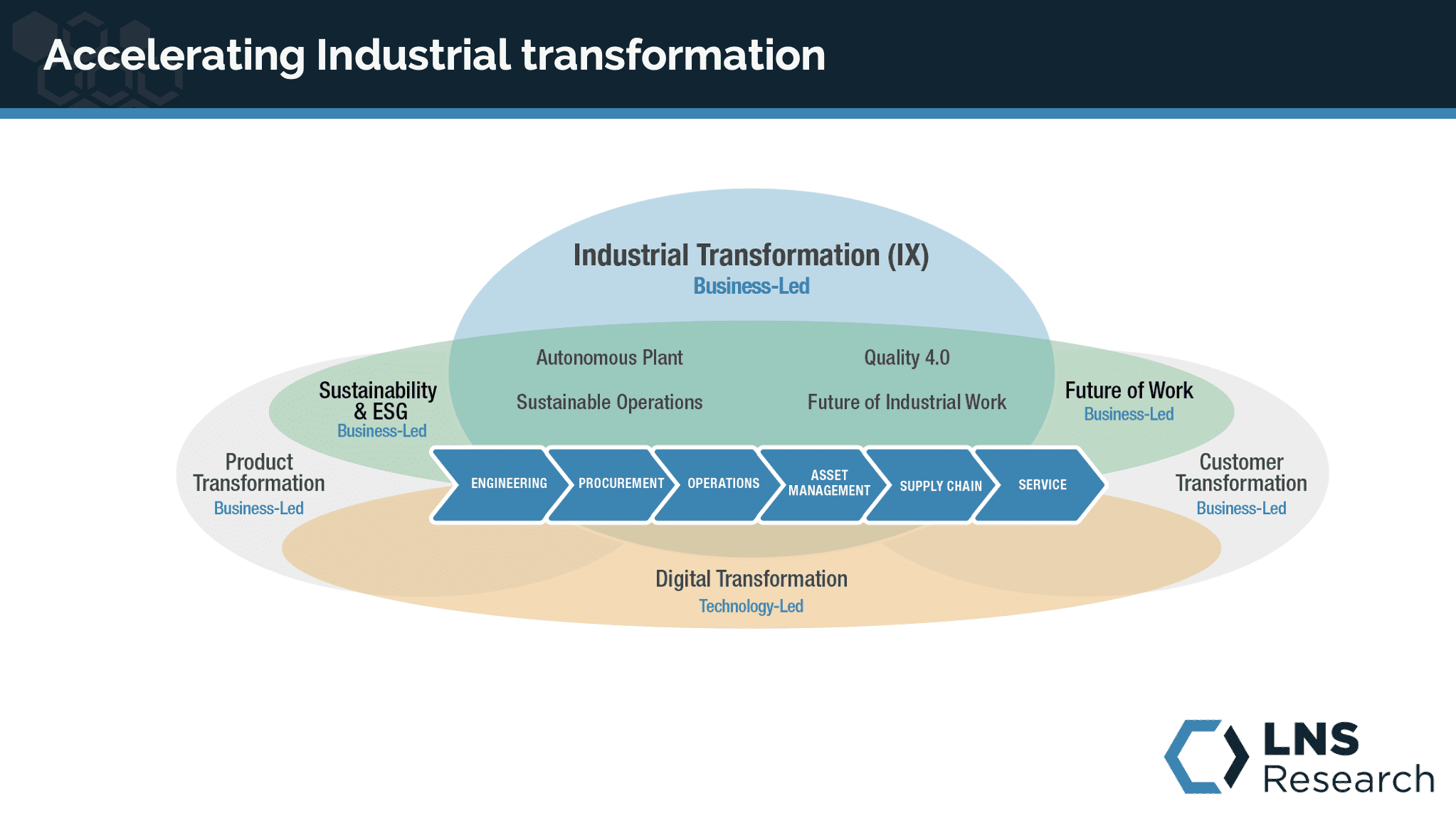

Here is another image from LNS Research that helps to visualize the expanded scope of what is involved in a broader Industry Transformation by manufacturing organizations. At its core is the digital thread to help connect each of these activities and provide manufacturers with a “single source of the truth” to assess performance and plot the way forward.

Now is an exciting time in the world of manufacturing. We are seeing firsthand a transformation in how a “digital first” strategy has quickly become the mainstream operating model. So many benefits are possible – and hopefully, a better path to a more sustainable future.

Looking back to 2002 when I saw the first 3D digital model of an industrial asset being manufactured seems like a bit of science fiction at the time. What a difference two decades can make. At that time, the vision was great, but the actual digital models were just early prototypes. I look forward to seeing what the next 20 years will bring!

Share this: