Editor’s note: Originally published in Field Service, a quarterly print magazine by Field Service Digital and Predix ServiceMax. Check out the full magazine in print or online.

Never underestimate the power of resource planning and the efficiencies that it drives.

That advice to field service organizations comes straight from Trey Keisler, CIO of supply chain at GE Power. Keisler, who ran the company’s field service IT division for nearly seven years, knows how greater efficiency can deliver significant financial returns over time—especially for a $15 billion power-generation service provider with more than 10,000 field service experts.

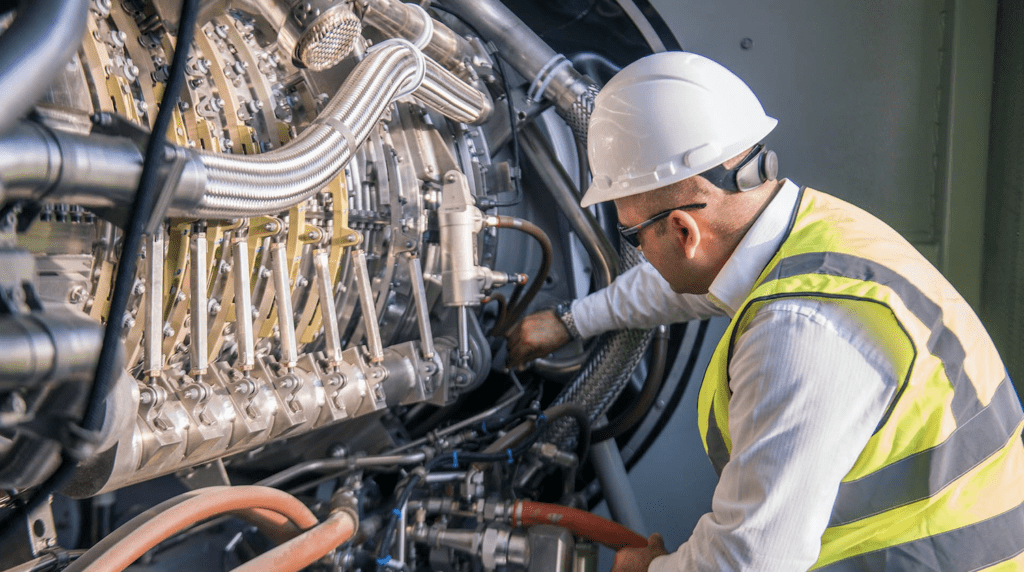

GE Power’s service team supports power-producing facilities in 150 countries, helping them to keep their gas turbines, steam turbines, generators and boilers running at peak output.

“The biggest cost for our customers, aside from fuel, is maintenance,” Keisler says. “So we’re constantly driving efficiencies inside GE Power to reduce costs for our customers and help them to be more competitive.”

The company’s continuous focus on improving field service efficiency and productivity drove its decision to implement the Predix ServiceMax field service management solution. At the start of the 2012 implementation, GE Power’s field service efficiency rate was around 69 percent. Today it’s up to 76 percent. A seven-point increase may not seem significant, until you consider that each point translates to roughly $5 million in savings to GE Power’s bottom line—or $35 million yearly.

More-Versatile Engineers, More-Accurate Resource Planning

Keisler attributes much of these savings to GE Power’s ability to serve its global customer base more effectively by simply “getting the right person to the right place at the right time,” along with the right parts and other resources to get the work done. He says that before implementing ServiceMax, aligning these attributes was “nearly impossible” for GE Power to do consistently, let alone expediently.

“The biggest cost for our customers, aside from fuel, is maintenance.” — Trey Keisler, CIO of supply chain, GE Power

For GE Power’s customers, the “right” person for a job isn’t necessarily a field engineer with the appropriate skills and certifications to perform the repair or upgrade. It could also include someone who has localized knowledge or expertise.

“One of the key things that our customers look for is local service—people who understand the local culture and environment,” Keisler says. “With ServiceMax, we can make sure that, where possible, we’re deploying people who are best suited to support our regional customers’ needs.”

GE Power is also using its modern service management platform to improve cross-utilization and cross-training of its field service experts. That, in turn, can help to further increase efficiency.

“When we train our field engineers to work on multiple types of equipment, they become even more valuable,” Keisler says. “Many people think of a field service engineer as a Maytag man. But our people are degreed mechanical and electrical engineers who perform highly technical service work for our customers, often in remote places of the world or under extreme conditions.”

Long-term staffing management is a critical activity for GE Power, because the company’s field engineers’ specialized skills are always in high demand.

“It can take about 18 months to get a field engineer trained and ready to be billable to a job,” says Keisler. “That’s why it’s extremely important to plan ahead up to 24 months or even longer for our staffing needs.”

ServiceMax’s dispatch console technology allows resource managers to assign work for long-term jobs more effectively by filtering through skill competencies, availability and location, features that led to a 10-percent boost in utilization.

“The data we’re collecting with ServiceMax, and the analytics we’re performing on top of it, help us to plan our long-term resource forecast more accurately, and drive our resource planning schedule through highs and lows,” Keisler says.

Laying the Foundation for Automated Dispatching

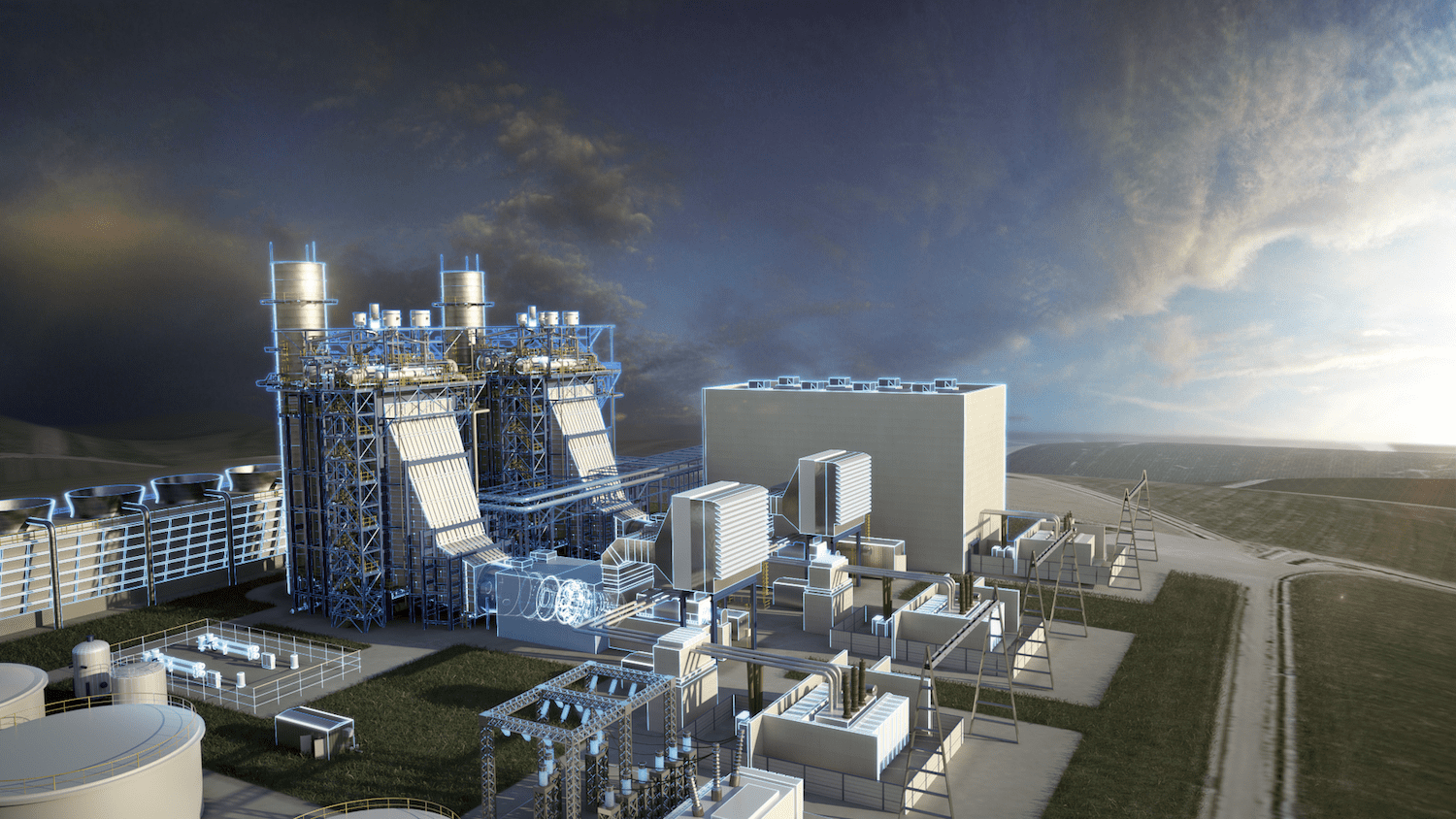

GE Power’s Monitoring and Diagnostics Center.

GE Power has a team of experts stationed at its Monitoring and Diagnostics Center in Atlanta, Ga. The team monitors 2,500 power assets around the world in real time, collecting more than 50,000 hours of operating data from sensors attached to customers’ equipment that produce electricity for about 400 million people.

In 2017, the team at the Center began using GE Digital’s Predix Asset Performance Management application to help prevent outages by increasing the reliability of power-generating equipment such as turbines and generators. Predix APM, which integrates with ServiceMax’s field service management application, draws on a deep catalog of analytics to identify patterns and trends in data that could indicate issues with a machine’s performance.

These strategic investments in powerful digital tools are meant to help GE Power reach its ultimate goal: help its customers achieve zero unplanned downtime.

“That’s really what the future of productivity for GE Power is all about,” Keisler says. “Through our use of Predix APM, ServiceMax, and advanced analytics, we can help our customers prevent forced outages.”

In the future that Keisler describes, the ServiceMax solution will be able to automatically dispatch GE Power’s field service experts to events when asset-monitoring sensors alert on equipment issues in real time.

“In this new world, we won’t need people to determine when to go to an event. We can let the equipment tell us when it’s time to provide service.” — Trey Keisler

“In this new world, we won’t need people to determine when to go to an event,” Keisler explains. “We can let the equipment tell us when it’s time to provide service. And ServiceMax can instantly dispatch the right people, parts and resources to get that service work done.”

The data that’s collected from these solutions will also help GE Power to develop new service offerings.

“For example, when we start pulling in market information, whether it’s weather data or spark spread fuel prices, we’ll be able to tell our customers when to spin their equipment up or down based on these conditions,” Keisler says. “We’ll also be able to determine how to balance the load between renewable power and fossil power.”

Meanwhile, GE Power is continuing to roll out Predix’s industrial applications in other parts of its business, including its supply chain and quality functions, so that it can further improve service delivery and asset performance, take advantage of connected asset data, and drive predictive analytics.

Images courtesy of GE Power

Share this: