In field service, there are some “sins” that, if habitual and left unchecked, lead your business down the path of unhappy customers, negative reviews, loss of sales — and ultimately irrelevance. How do you guard against all that? Avoid making these goofs and remember that when customers feel valued, attended to, and appreciated by your company, they’re more likely to forgive the occasional mistake. Here are the seven deadliest sins to avoid at all costs:

In field service, there are some “sins” that, if habitual and left unchecked, lead your business down the path of unhappy customers, negative reviews, loss of sales — and ultimately irrelevance. How do you guard against all that? Avoid making these goofs and remember that when customers feel valued, attended to, and appreciated by your company, they’re more likely to forgive the occasional mistake. Here are the seven deadliest sins to avoid at all costs:

1. Arriving Late

Customers often have to rearrange their schedule to accommodate a service call. So when a technician is late, customers (rightly) get upset. Besides the money they’re paying a technician to perform a job, taking time off work to be home for the call costs money, too.

“[If] you tell the customer you’re going to be there in two hours and the tech arrives in three hours, that customer is one hour frustrated,” says Arthur V. Hill, PhD, the associate dean of MBA programs at the Carlson School of Management at the University of Minnesota, and author of the books The Encyclopedia of Operations Management and Field Service Management: An Integrated Approach to Increasing Customer Satisfaction. “Even if you arrive on time, the customer is not necessarily satisfied — just less frustrated.”

The key is to set realistic expectations on the front end with scheduling. But no matter how well prepared, situations inevitably occur that push a tech behind schedule. When it happens, communicate with the customer. Apologize for the inconvenience and provide an updated arrival time. The “heads up” shows customers respect for their time and enables them to adjust their schedule, helping ease the frustration they might feel.

2. Arriving Unprepared

The tech arrives, examines the equipment, but realizes he doesn’t have the right parts in the truck to fix the problem. What could have been repaired during the initial service call now requires a call-back, costing your company money through lost time, the fuel costs of rolling a second truck, and extended downtime for the customer.

“It’s really hard to always have all the parts you need because you’d have to haul an entire machine in your vehicle to have all the possible parts,” Hill says, “but you can reduce call-backs with better preparation. Get a clear sense of the problem up front so techs can be more likely to bring parts required. If you don’t have the parts in stock, you should have sources that can help expedite parts delivery to reduce the customer’s downtime.”

This is where a robust front-end customer service channel is so important. By properly diagnosing the problem early on, during the initial call to customer support, field-service managers can be better assured their techs are heading out into the field with the right information, the right parts, and in the best possible position to get the job done. More advanced systems like parts inventory management programs can help automate this process, too, giving managers a view into what’s on board every tech’s truck. Either way, a tech without tools isn’t much good to anyone.

3. Not Following Up

So the tech didn’t have the right part, and had to schedule a call-back appointment for two days later. But two days later, no one shows up. When the customer calls in to find out where the tech is, the response is, “Oh yeah, sorry. We’re still waiting on that part to come in.” Clearly, that’s a no-no.

“Some people make promises thinking that will satisfy the customer in the moment, but in essence you end up causing a lot of frustration,” Hill says. “The critical thing to do is to be very careful about making promises. Don’t make promises you can’t keep.”

When there are delays or any other type of “bad news,” be the first to inform the customer, with an action plan for how your company will remedy the situation. And follow through. This proactive approach will help diffuse the situation before it blows up into a crisis.

4. Handing Off Customers to a Middleman

Hill, who also served as a consultant to 3M for its medical-imaging equipment field service operations for 10 years, describes a challenge the company encountered with its call dispatching processes prior to adjusting its approach. “At 3M, the customer would call the national dispatch center, who in turn would call the local dispatch center, who would then call the technician,” he says. “But so much information [about the customer’s issue] would get lost. You don’t want too many people in the communication chain because then no one really owns the problem; no one owns the customer.”

The solution, Hill says, was to assign a primary technician to customer accounts. “This way, the tech owns the account. If there is a problem, the call goes into the national dispatch, who then contacts the primary tech directly — and we would dispatch that tech whenever possible.”

Especially for big, complicated, or long-standing accounts, having a primary technician who knows the ins and outs of the equipment in question is a smart move.

5. Ignoring Customer Feedback

Without feedback, a company can’t really know how it’s doing, or how well its technician are performing. Collecting feedback shouldn’t be an option — it should be mandatory. “At 3M, we had evidence that the techs, if they had a bad service call, would ‘accidentally’ forget to leave the [customer feedback] card,” Hill says. “And even when they left the card, the problem was a low response rate. So, you weren’t really getting accurate data — the feedback you need to drive positive change.”

To improve response, 3M trained its “call takers” to use their down time every day to call five customers to collect feedback. “We got a lot of data that way,” Hill says. “If the survey scored a 5 out of total of 5 points possible, we wouldn’t do anything. If it was 4 out of 5, we may have the tech call the customer for additional feedback. If it was 3 out of 5, we’d have the service manager call the customer. If it was a 2 or a 1, we actually had a VP call the customer. So the VPs were hearing really negative information. It turned into a great system for getting the customer’s pain to the right place in the organization.”

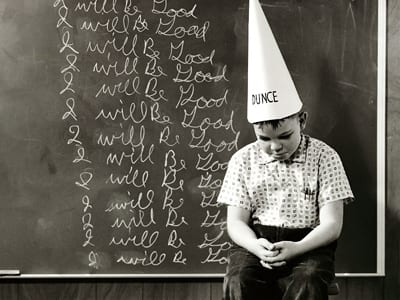

6. Talking Down to Customers

Most customers aren’t experts in the equipment your company services. But sometimes technicians can take that for granted and get frustrated with customers who “don’t have a clue.” Or they go out of their way to make customers feel bad for hiring the last company, who probably “screwed up the repair.”

Whatever the case, customers resent being talked down to and will take their future business elsewhere, no matter how smart and skilled your tech might be.

Train techs to be patient — to take time to walk customers step-by-by through the process, explaining (in layman’s terms) why a certain procedure or part is necessary to fix the issue. This approach helps build trust with customers, making them more likely to entrust your company with future service opportunities.

7. Over-Relying on Technology

While technologies for customer relationship management (CRM), enterprise resource management (ERP), inventory management, and route-optimization systems are all useful tools for creating operational efficiencies and cost savings, Hill offers this word of caution: “Don’t look for a technology quick-fix. I’ve seen companies do that, where they want some new computer system to solve all their problems, and it ends up being a costly disaster.”

Instead, Hill says, make technology conform to your business. “Keep in mind, [field service] is primarily a people business. So use technology that supports your people in how they work best, as leverage to take service to an even higher level.”

Share this: