A smart approach to service design allows astronauts to overcome harsh conditions and complete vital upgrades in orbit.

Since its 1990 launch, The Hubble Space Telescope has helped scientists to understand how planets form, as well as the mysteries of dark matter, the universe’s age and other significant discoveries. But it has also revealed valuable lessons about how product design impacts maintenance and repair — lessons that NASA still uses when building satellites today.

Hubble’s longevity stems from it being one of the first spacecraft designed to receive repairs and upgrades during orbit. NASA recently celebrated the 25-year anniversary of the first Hubble servicing mission, which, among other tasks, resolved a major issue with the telescope’s mirror. After the success of four subsequent Hubble servicing missions, NASA formalized the satellite maintenance program by creating the Satellite Servicing Projects Division (SSPD).

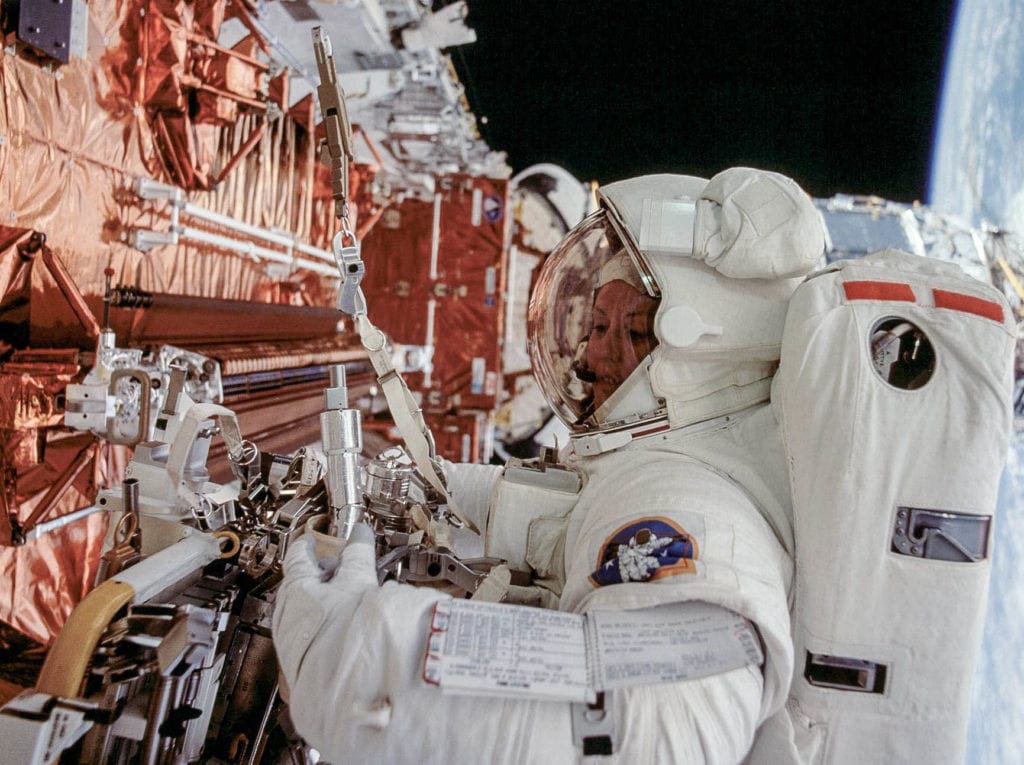

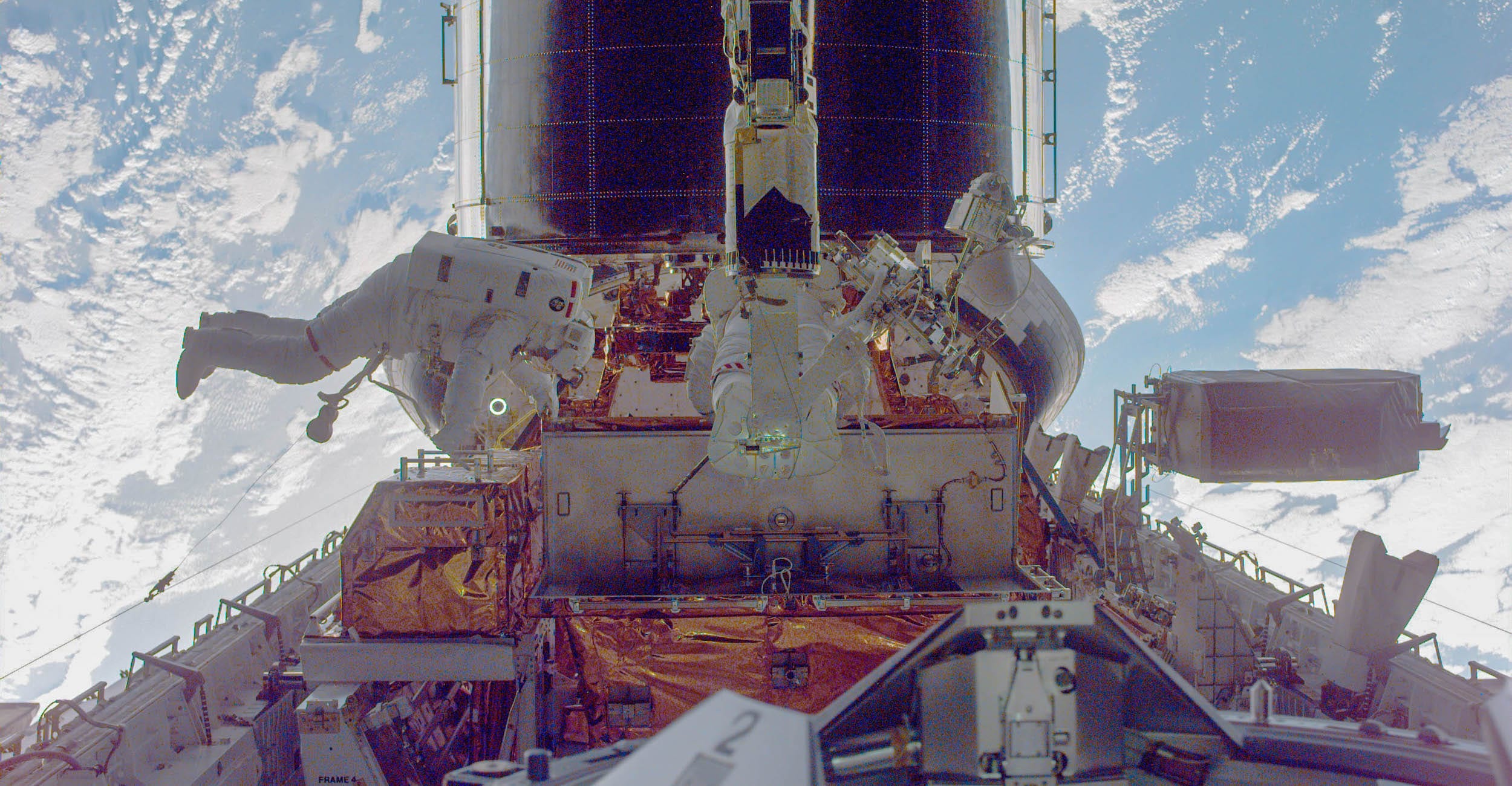

Astronaut Kathryn C. Thornton performs repair work on the Hubble Space Telescope during the original repair operation in December 1993. Image: NASA

Continuing the Hubble Servicing Legacy

The mission of SSPD is to take learnings from the Hubble program and continue the practice of servicing satellites in space. So far, the agency has completed 10 on-orbit service missions and technology demonstrations, and it is also working on specialized tools for International Space Station repair missions. The primary capabilities that SSPD focuses on are colloquially known as the “five Rs” — remote inspection, relocation, refueling, repair and replacement. Satellite servicing extends the lifetimes of spacecraft, making space exploration more economical and sustainable, while also furthering scientific research. By upgrading satellites with emerging technologies, NASA can collect larger quantities of better data from distant regions of the universe.

Astronauts aboard NASA’s Robotic Refueling Mission 3, part of a series of missions to test tools and technologies to refuel and repair satellites in space, use the Cryogen Servicing Tool to test the storage and transfer of liquid methane in space for the first time. This capability will help crewed missions embark on longer journeys, such as to the moon and Mars. Image: NASA

“Rather than building a telescope and throwing it away, you can increase the size of the aperture along with incorporating improved instrumentation,” says Preston Burch, associate director of SSPD. “That’s the kind of thing that will enable great discoveries like those we’ve seen with Hubble in the past 25 years.”

Satellite servicing and repair technologies are critical for NASA’s most ambitious projects, including the proposed lunar space station and manned trips to Mars. Due to their length and complexity, both of these endeavors would require the ability to service the spacecrafts, replenish propellants and sustain human life on the journeys.

Designed for Service

SSPD’s work has demonstrated that designing spacecraft for service from the start can greatly lower costs, minimize risk and increase the mission’s chance of success. For example, Hubble was built with modular components that store self-contained “black boxes”of avionics systems. When it’s time for satellite repairs, maintenance, or upgrades, astronauts can easily replace one module with another, rather than having to reach the delicate instruments and wires inside.

SSPD developed the Cooperative Service Valve (CSV), which, similar to a car’s gas tank, allows astronauts or robots to safely refuel satellites without leaking toxic propellants. One simple but powerful Hubble innovation was to mount cameras on astronauts’ helmets, allowing specialized technicians back on earth to watch and assist during live video streams of satellite repairs in space.

“It was like our people in the control center were perched on the shoulder of the astronaut. We could provide this whole army of several hundred engineers with the capability to immediately respond to and help out while the astronaut was doing the servicing work out in the cargo bay,” Burch says. “That is a tremendously powerful capability and one of the things that was indispensable to mission success on these servicing missions.”

Astronauts and Robots: A Tag-Team Service Effort in Zero Gravity

Astronauts who toil in outer space have to contend with zero gravity while maneuvering in bulky space suits that provide limited oxygen. In some cases, it makes more sense to use robots in satellite repair, since they can withstand the harsh conditions for longer periods of time and can reach locations in space that astronauts cannot.

SSPD’s current priority is to develop procedures and specialized tools for an upcoming mission that will send Restore-L, a robotic servicing spacecraft, to refuel Landsat 7, a live satellite that was not originally designed to be serviced in space. The Restore-L spacecraft will have to autonomously locate the satellite in orbit, navigate to it, determine the area of the Landsat 7 that requires servicing, grasp the satellite and dock itself before it can begin repair work.

SEE ALSO: Space Plumbers: The Most Difficult Job in Service?

But the challenge with autonomous servicing is that robots are not as adaptable as humans when faced with an unexpected problem, so Burch says it’s best to use a combination of the two methods when possible.

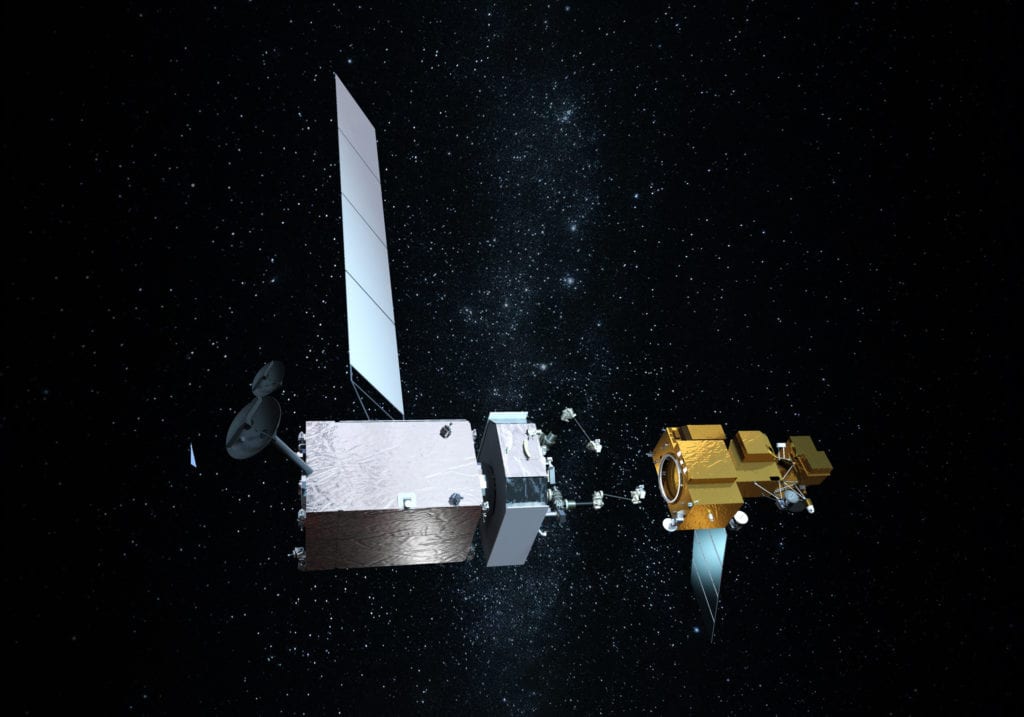

A rendering of the autonomous Restore-L servicer extending its robotic arm to grasp and refuel a satellite in orbit. This mission is scheduled to launch in 2020. Image: NASA

“There are roles for both of them to play,” explains Burch. “We should be using the robotic ops to help the astronaut, to reduce the risk and the fatigue, and to let the astronauts do the things that they are good at, working together collaboratively in an efficient way to achieve the mission objective.”

Enabling a Future U.S. Industry

The innovations developed at SSPD can be applied to a vast array of projects within both NASA and private sector, including the telecommunications industry. In addition to repairing satellites, Burch and his team aspire to see SSPD’s practices used in projects like debris management, propellant depots (a.k.a. space gas stations) and even in-orbit spacecraft assembly.

SSPD hosts yearly events to demonstrate their latest technologies and designs and transfer them to any interested domestic companies, with hopes of jumpstarting a competitive satellite servicing market and positioning the United States as a leader of this burgeoning industry. SSPD has already issued a license for their CSV to two companies, and the division continues to find new opportunities to collaborate with the private sector.

Ultimately, the ability to maintain, upgrade and extend the lifespan of satellites will lead to space operations that are more efficient and cost-effective, Burch says. “We say one of the cornerstones of our division is to share this technology with everybody because we really want to encourage the development of a satellite servicing industry.”

Share this: