Editor’s note: A version of this story by Tomas Kellner originally appeared on GE Reports, a site that covers GE’s industrial transformation.

When Vincent Schellings started designing wind turbines two decades ago, he frequently polled his colleagues about what they thought was the biggest turbine they could build. “We didn’t get much further than a 3-megawatt machine with a 100-meter rotor,” he recalls. “But even that seemed too big.”

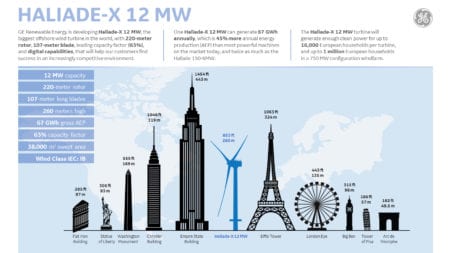

Schellings, 44, never stopped asking that question. Today, he leads the team at GE Renewable Energy developing the world’s largest wind turbine, one that dwarfs his youthful musings. This veritable behemoth will loom 260 meters tall from base to blade tips — 1 meter taller than New York’s famous 30 Rockefeller Plaza tower. With blades as long as a football field, the rotor will measure a beefy 220 meters in diameter.

These turbines come with a 12-megawatt generator sitting 150 meters above the waves. Each will be capable of powering 16,000 homes and producing 67 gigawatt-hours per year, based on wind conditions on a typical German North Sea site — that’s 45 percent more energy than any other offshore wind turbine available today.

“We asked ourselves ‘What is the biggest rotor we would still feel comfortable with?’ and then we pushed ourselves some more,” Schellings recalls. “From a technology perspective, it seems like a stretch. But we know it’s doable. The beauty of the turbine is that it gives an edge over the competition. There’s nothing like this. Not even close.”

Today, the largest wind turbine has a rotor with a 180-meter diameter, but that is a prototype. The biggest operating turbines have rotors topping 164 meters and generators rated up to 9.5 megawatts. “We decided to leapfrog the competition,” Schellings says.

The size matters. The huge rotor allows the engineers to catch a lot more wind and ramp up what the industry calls “capacity factor.” This number describes the amount of power the turbine can produce per year at a given site, versus the energy it could have generated had it run full power all the time. GE’s Haliade-X clocks in at 63 percent, “five to seven points higher than the competition,” Schellings says. “Basically, every point of capacity factor is worth $7 million per 100 megawatts for our customers. That’s a nice upside.”

There are other benefits. The new 12-megawatt design will allow operators to build wind farms with fewer turbines, lay fewer cables, reduce construction, maintenance and other capital costs, and recoup their investment faster.

“This helps the customers when they are competing at auctions to build offshore farms and enter the lowest bid per kilowatt-hour,” says John Lavelle, the CEO of GE Renewable Energy’s Offshore Wind unit. He and his team are starting to talk to companies interested in building wind farms in the next few years using equipment that will start shipping in 2021. “We are trying to target those bidders, so they can factor in the value we can bring. If they win, we win.”

Offshore wind is the fastest-growing renewable energy segment. “The renewables industry took more than 20 years to install the first 17 GW of offshore wind,” said Jérôme Pécresse, president and CEO of GE Renewable Energy. “Today, the industry forecasts that it will install more than 90 GW over the next 12 years. This is being driven by lower cost of electricity from scale and technology. The Haliade-X will set a new benchmark for cost of electricity and drive more offshore growth.”

SEE ALSO: Offshore Wind Energy: A Job Creation Windfall for the Service Industry?

Huge wind turbines like the Haliade-X will play a key part, but how do you build one? GE, which is investing $400 million in the project, started exploring the idea two years ago. After deciding on the diameter of the rotor, Schellings’ team worked backwards to calculate the magnitude of the generator and the size of the tower supporting both.

Read the full article at GE Reports.

Share this: