It’s easy to take field service technicians for granted — that is, until an A/C unit breaks during the dog days of summer or a critical piece of manufacturing equipment goes down during production. Otherwise, service technicians often work behind the scenes to fix the equipment people rely on to travel, work and stay healthy.

It’s easy to take field service technicians for granted — that is, until an A/C unit breaks during the dog days of summer or a critical piece of manufacturing equipment goes down during production. Otherwise, service technicians often work behind the scenes to fix the equipment people rely on to travel, work and stay healthy.

One resource that people use every day but don’t think twice about? City streets. Sure, people might complain when a scofflaw illegally dumps something in front of their house, or might get angry when they forget to move their car on street sweeping day — but few give much thought to the people who work around-the-clock to keep the streets tidy. Just ask Octavio Sanchez, an equipment supervisor with the Oakland (Calif.) Public Works Agency. Sanchez and his crew keep the sweepers running and the brushes spinning on Oakland’s more than 800 miles of city streets.

The Equipment

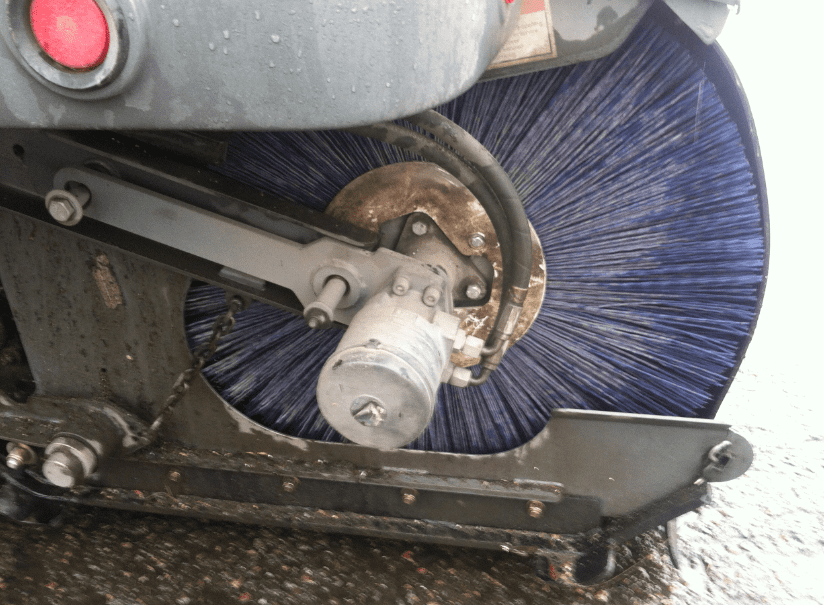

Oakland uses two types of street sweepers. The Elgin Broom Bear features two mechanical gutter brooms on both sides of the street sweeper truck and a main broom in the back. The gutter brooms shoot debris to the center of the vehicle, where it’s swept up by the main broom and funneled onto a conveyer that deposits the junk in the hopper. The second type, made by Tymco, uses two gutter brooms that shoot debris into the center of the truck, where a powerful vacuum sucks it into the hopper.

Both models are modified Freightliner FL70 trucks, which the manufacturers retrofit with the brooms, vacuums, hoses and other attachments needed to tackle dirty city streets.

The Crew

The city employs 17 drivers to operate its fleet of 14 street sweepers. The drivers work on rotating day and swing shifts to clean both sides of the roughly 800 miles of public streets.

“On a normal day, from 8 a.m. until 4:30 p.m. we’ll have 10 to 11 routes being swept,” says Sanchez. “In the evening, we’ll have about seven to eight drivers working from 11 p.m. until about seven in the morning.”

The street sweepers travel between 80 and 100 miles per shift, with 50 or fewer “gutter miles” when the trucks clean their assigned routes.

The miles add up, especially since street sweepers work double shifts. As the swing shift equipment supervisor, Sanchez oversees the mechanics in the heavy equipment shop who keep industrial-size equipment like fire engines and street sweepers in working order. The heavy equipment shop staff includes 14 mechanics, plus support staff who inspect equipment and handle quick fixes and preventative maintenance.There’s also a parts technician, who tracks inventory, handles orders and accounts for every part that passes through the shop. It’s an important job, not only to ensure the mechanics have the needed parts but also to report back to the city (and taxpayers).

“We’re a municipality, so we have to account for everything that we do,” says Sanchez.

The Service

Before the sweepers hit the streets every evening, Sanchez and his crew wash them, clean debris from the frame and grease all bearings and moving components. They also perform oil changes and other preventative maintenance that every vehicle needs. The life expectancy of a street sweeper is about five years, according to Sanchez.

Before the sweepers hit the streets every evening, Sanchez and his crew wash them, clean debris from the frame and grease all bearings and moving components. They also perform oil changes and other preventative maintenance that every vehicle needs. The life expectancy of a street sweeper is about five years, according to Sanchez.

These are complex machines, though, with parts not found on your average work truck.

Take the gutter brushes, for example. For a street sweeper that works double shifts, Sanchez says his team will replace the steel circular gutter brushes every three days. The main brush at the rear, which is made of industrial-grade plastic, gets replaced roughly every two weeks.

“It depends on the operator, the debris that’s out there and the road conditions,” says Sanchez.

The faster the brush travels, and the more down force the operator applies, the faster the brush will wear out. It also depends on what’s picked up — and a lot of weird stuff gets picked up. The weirdest?

“You sure you want to go there?” Sanchez jokes. Beyond normal dirt and gutter debris, Sanchez says that clothes, roadkill and even car parts are common.

The Tools

Outside of the standard wrenches, automatic hand tools and screw drivers in every mechanic’s toolbox, Sanchez and his crew rely on several specialized tools.

“One of the tools that we can’t live without are big truck lifts,” says Sanchez. “We need those in order to get underneath the machines to service them.”

The mechanics also rely on a laptop and software that can pull codes from the vehicles’ computers if, say, the check engine light comes on.

Pelican SE series sweeper. Rubber dirt shoes adjustment. How to raise them.

The ac in our frieghtliner sweepeer truck barely blows cold air. What is the kcause of it?

Clean the cabin filter at least once a week

The street sweeper I operate leaves a dirt trail

Could be multiple things causing your sweeper to leave a winrow But I’ll go with the most common reason which would be slow down however your sweeper gets the material to the hopper. Whatever is feeding it there’s too much and it can’t get it all up leaving that trail behind. Try slowing down.

all the brooms deploy but will not rotate they try everything else hydraulic works and fluid is full ant ideas